History is something I love, because the more we learn from it, the more we understand the future.

In 1968 the Russians repeatedly told the American people “There is no way you will go to the moon, we have better technology and we haven’t even thought about it, there is no way you will achieve it”….The rest as we all know is history.

We Are Ready to Laser Mark Surgical Instruments!

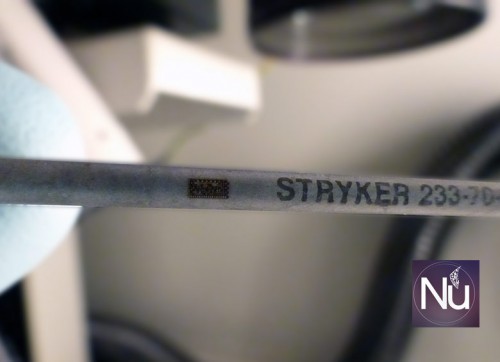

One of the most important task following the FDA UDI rule (Unique Device Identification) is the marking and retrofitting of each instrument inside the hospital's supply chain with a 2D DataMatrix code. This barcode is universal (It can be GS1 as well) and can be read by any barcode reader, as well by any tracking system available in the market.

Surgical instruments laser marking on site. Laser marks with ZERO rust

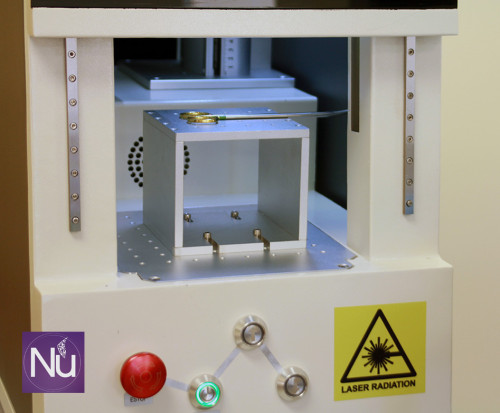

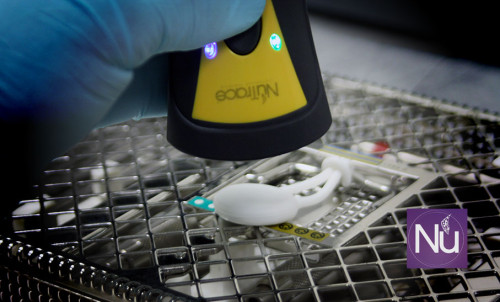

We have been moving the laser unit around hospitals while running some tests and most importantly, perfecting the inside process for laser marking surgical instruments.

Surgical instruments laser marking. Is is just simple science

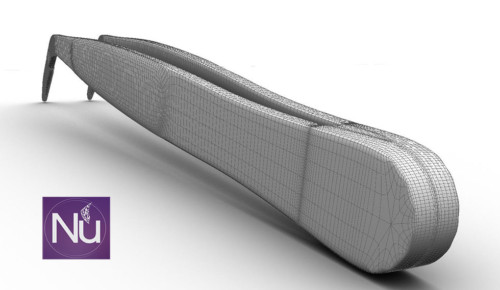

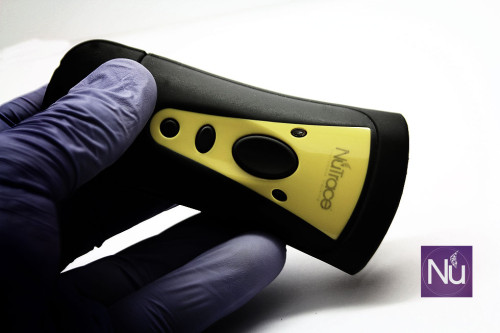

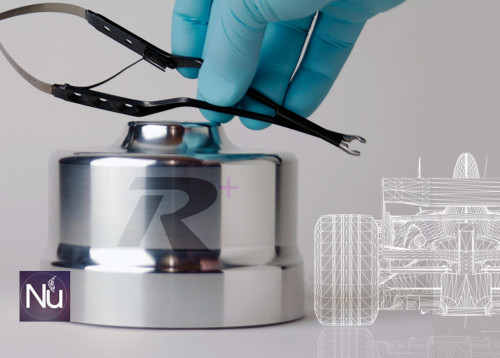

Presenting the new NuTrace Fiber Laser exclusively designed for the SPD.

Surgical laser tags for surgical instruments trays identification.

It is known that common labels applied to surgical trays won't last for long. The washer, sterilizer fades the ink out and make them pretty much

unreadable, at any moment when needed they won't read.

When we first started studying the physics of lasers, wavelengths, metals etc, it took me back to my early days of high school chem lab where I learned the basics of metals, the periodic table (yes, one-by-one with atomic mass, atomic number and symbol names). I was surprised back then to learn that the only element that rusts in nature is iron (Fe).

Surgical Instrument Laser Marking brings you a great control of each single instrument in the supply chain

But please make not mistake, it is one of the most sensitive variables in the instrument tracking process.

Tracking at instrument level shouldn't be painful

These days with the concerns over superbugs, prion diseases and other common issues related to instruments found in the operating room, instrument traceability is a must have. Tracking at the "Tray Level" really will not fix any of the problems above.

I want to start this article with one fact, I love my "job" and if you ask me what it is that makes me love it so much; my answer would be only one word “Learning”.

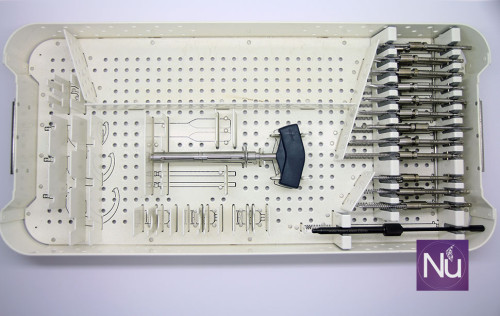

Laser Marking a Nezhat Instrument Set

We received a Nezhat set from a customer as part of NuTrace Lean process implementation on site for FDA UDI.

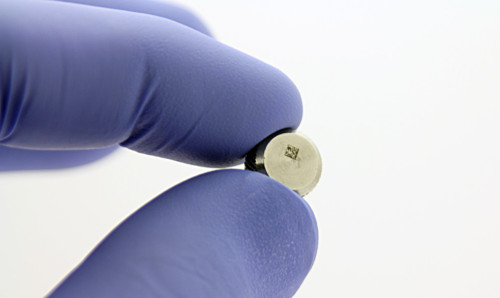

Surgical Instrument Laser Marking, 800 Microns

We just broke our own record marking a surgical instrument (800 Microns 2D code on an irrigation needle).

We want to thanks all visitor that came to our booth at IAHCSMM 2016 in San Antonio.

Thanks to the North Carolina chapter for IAHCSMM for a great 2016 meeting.

If you are tracking at the tray level and are ready to track at the instrument level, this is your opportunity to have it all with NuTrace.

We will have have everything you need to know about NuTrace and our Lean Process. Our booth (1226) will include info on the planning of surgical sets, see instruments on our arrival/departure display, our R+ reader which is the fastest 2D reader in the world, and our NuTrace fiber laser.

Branding is all around you.Look inside your hospital, you will see brands popping out around you, from the soap dispenser to the instrument you are holding right now in your hand, it is all about branding.

Operation Room and Sterile Processing Department. Best Practices Managing Communication.

One of the most critical key elements for success in healthcare is communication and information management.

The difference between tracking and inventory management are substantially different and seems to be a confusing topic in healthcare, especially within the instrument tracking world.

In some patients undergoing neurosurgery, a CJD diagnosis that is not suspected before the procedure may be confirmed during or after neurosurgery.

I had the pleasure of attending the North Carolina Sterile Processing meeting in Winston Salem, NC the first week of November.

If you want to see the real benefit of surgical instrument laser etching

or container's lids laser marking, just contact us,

We want to sincerely thank the Tennessee iahcsmm chapter for inviting us to their past meeting in Knoxville, TN.

We received great assistance and very positive comments from our total instrument tracking system.

We received some small instruments from a large facility in North Carolina asking us if we could place marks on them.

Welcome to NuTrace we will give you a peak of what we do in our marking lab.

We are proud to announce the version 1.0 of our 2D reader IPhone app. With it, you will be able to read 2D DataMatrix codes directly to your IPhone.

NuTrace laser to mark surgical instruments is here UDI

We are happy to announce we are testing now our new NuTrace fiber laser, first laser in the world exclusively designed for the Sterile Processing Department to laser mark quickly and inexpensively surgical instruments .

Our instrument trays with integrated Steri-ID are made in accordance with the same quality criteria as our standard Sterisystem instrument trays.

Coming this Fall, the first tabletop class 1 fiber laser specifically designed to DataMatrix surgical instruments.

NuTrace is a powerful tool not only to track at the instrument level; it can help the O.R plan the instruments to be used on patients & also helps the tech in the SPD identify and recognize every set, tray and instrument in their inventory.

More coming soon.

Coming very soon inside NuTrace instrument tracking at no additional cost RFID tags to track your sets and trays among the datamatrix marked on the instruments.

Coming soon a complete view of our process of instrument marking with fiber laser. "Marking surgical instruments is not complex, marking complex surgical instruments is our specialty"

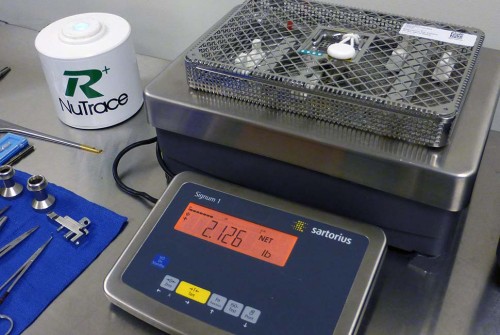

AORN and the Association for the Advancement of Medical Instrumentation (AAMI) recommend that instrument sets and trays prepared for sterilization not exceed 25 pounds. This weight limit includes the combined weight of the pan and the instruments.

Tracking your Endoscope shouldn't be complex nor expensive. The picture above: Colonoscope 22 (Red coded) serial number 677763 ready for HLD (High Level Disinfection) sink 3, washer 28890.

We will make your scopes smarter and traceable, leading to an increase in quality care control.

NuTrace Endo, total solution for scope tracking coming soon to GI.

Today's healthcare we want to trace and track every possible instrument without the need to place or glue any kind of foreign objects.

Marking Surgical Instruments with NuLaser

YAG laser is a safe, fast and dynamic way to mark surgical instruments.

NuTrace at NCAHCSP

Thank you to the North Carolina Association for Hospital Central Service Professionals for allowing us to participate in their conference at Myrtle Beach, SC.

At NuTrace, we see the SPD as a production line rather than another department in the hospital. Such movement of surgical instruments creates an immense amount of information, historicity and generated data. In order to optimally perform, the SPD must reign in such information to return each product to the specific client (instrument to patient).

What is instrument tracking?

The picture above shows two different DataMatrix marks:

With NuMark we have perfected a way to safely and easily....

We ran the first test under autoclavable conditions to test the healthcare glue we will be using with the NuTags. Continuous cycles each 30 minutes long at 270 F to test consistency of the glue. Perfect bond!

Evaluating our NuTrace™ R+ 2D reader in a major SPD department.

For us is not just track instruments, but bringing the communication

If you need customized aluminum tags, don't look further NuTag is here.

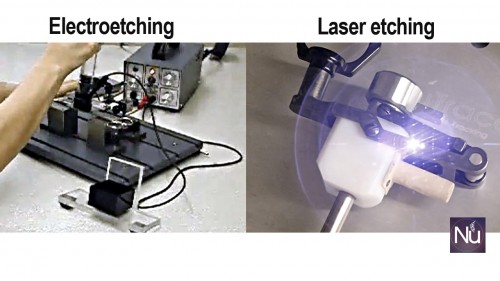

We received a call from a medical facility asking us to assist them with DataMatrix on 10,000 of their instruments with the use of electrolysis.

There so many techniques in the market today for DataMatrix marking (Dot pin, Electrolysis, Spray chemical with C02 etc).

The beginning of good surgical tracking starts with a very good DataMatrix mark, been sure can be read it by 2D readers.

We will look the differences between RFID and DataMatrix.

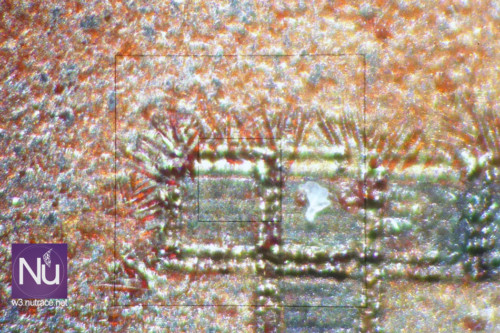

The bacteria growing in the DataMatrix mark

Bacteria growing on DataMatrix surgical instrument mark

.

Recent studies centered around instrument marking specifically etching systems have drawn red flags.